Gas handling devices

Reduce the amount of free gas on the pump intake

Gas handling devices prevent cavitation and gas locking, ensure the optimal pump performance, and increase the efficiency of the equipment. The principle of operation of the Advanced Gas Handlers is to reduce the diameter of the gas bubbles in the pumped-out gas-liquid mixture (GLM). Gas separators remove the free gas from the pumped liquid. The use of centrifugal gas separators is the most reliable means of protecting the ESP from the harmful effects of free gas.

Key advantages

1

Extends the lifetime of the ESP system2

Improves its performance3

Ensures the absence of impuritiesTechnical characteristics

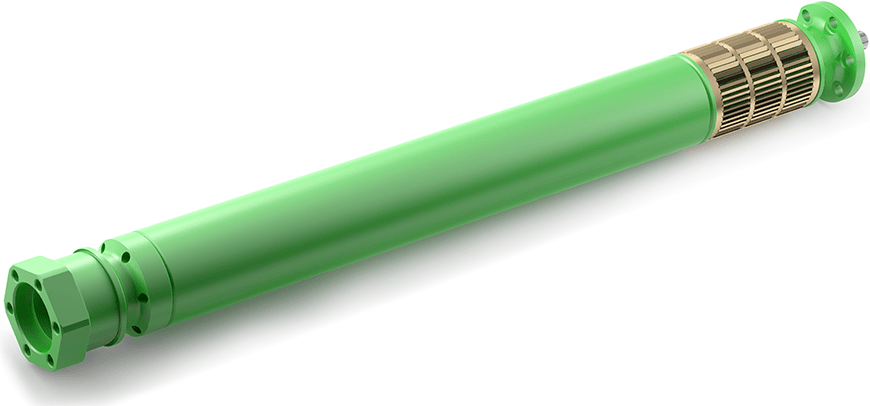

Gas separator

Minimum casing ID, inch

3.23

4.7

4.91

6.04

Housing OD, inch

2.72

3.62

4.06

5.35

Operation range, blpd

75-750

190-1900

190-3800

2000-15000

Gas separation, %

70

70

70

70

Gas handler

Minimum casing ID, inch

3.23

3.74

4.7

4.91

Housing OD, inch

2.72

3.19

3.62

4.06

Operation range, blpd

110-600

120-750

90-1900

190-6300

Gas separator-Handler

Minimum casing ID, inch

4.7

4.91

Housing OD, inch

3.62

4.06

Operation range, blpd

190-1900

190-6300

Gas separation, %

70

75

Design features

Gas Separators

- reduce the amount of free gas in the formation fluid at the pump intake;

- protect from gaslocks appearing;

- provide stable performance of ESP;

- increase MTBF (Mean Time Before Failure).

- reduce the amount of free gas in the formation fluid at the pump intake;

- protect from gaslocks appearing;

- provide stable performance of ESP;

- increase MTBF (Mean Time Before Failure).

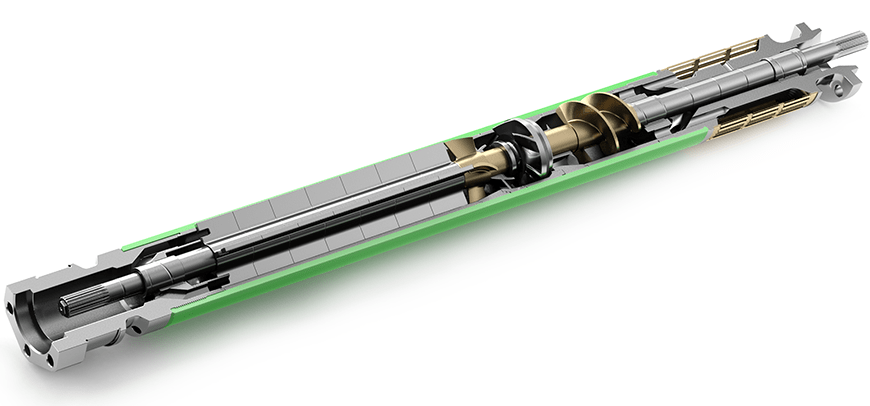

Gas Handler

- converts reservoir fluid into the homogeneous mixture;

- eliminates or minimizes the influence of free gas on stages;

- reduce flow vibration and pulsation in oil well tubing;

- provides the the pump KPI efficiency;

- reduce spurging.

- converts reservoir fluid into the homogeneous mixture;

- eliminates or minimizes the influence of free gas on stages;

- reduce flow vibration and pulsation in oil well tubing;

- provides the the pump KPI efficiency;

- reduce spurging.

Gas Separator - Handler

- reduce the amount of free gas;

- dispense gas inclusions;

- converts reservoir fluid into the homogeneous mixture at pump intake ;

- installed in wells with especially high GOR (gas to oil ratio), where nither gas separators, nor the dispensers can't provide stable ESP performance.

- reduce the amount of free gas;

- dispense gas inclusions;

- converts reservoir fluid into the homogeneous mixture at pump intake ;

- installed in wells with especially high GOR (gas to oil ratio), where nither gas separators, nor the dispensers can't provide stable ESP performance.